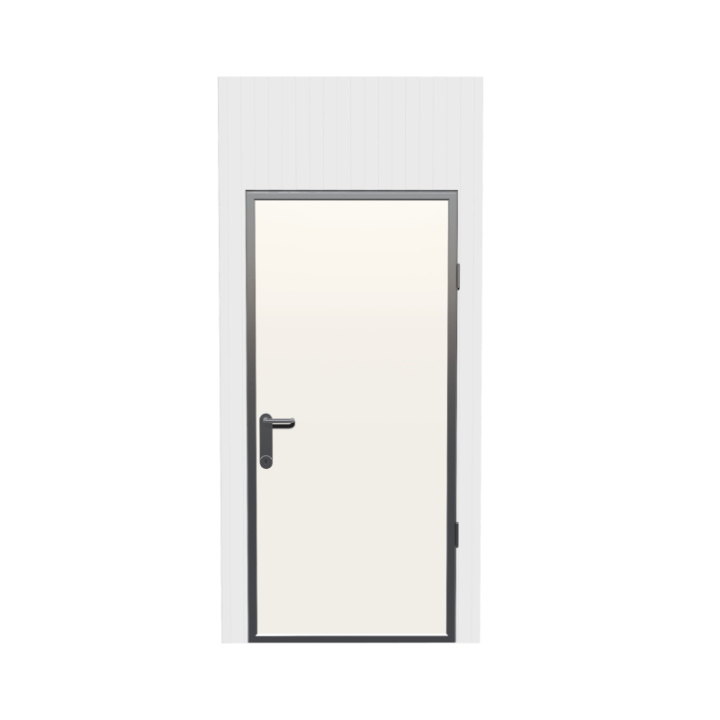

Slide Monorail Door

- Home

- portfolio

- Cold Room Doors

- Slide Monorail Door

- Slide Monorail Door

Slide Monorail Door

✓ FRP composite construction

✓ 1.5 mm AMB (antimicrobial) FRP, painted sheet or stainless surface

✓ EPDM rubber based seal system

✓ Seamless surface in the use of 1.5 mm AMB (antimicrobial) CTP

✓ Desired color option on the door leaf

✓ Door leaf and frame, anodized aluminum preventing heat transfer

✓ Door leaf, 42 kg/m³ high pressure polyurethane injection

✓ 220 volt, 25 w/m silicon based resistor on frozen enclosure doors

✓ Aluminum profile with resistance on the floor

The Cold Room Monorail Door is a technical marvel designed to provide unparalleled functionality and efficiency in cold storage environments. This specialized door is engineered with precision to meet the rigorous demands of various industries, ensuring optimal temperature control, ease of access, and robust insulation. In this article, we delve into the technical intricacies of the Cold Room Monorail Door and explore the diverse areas where it finds its indispensable utility.

Versatile Applications: The Cold Room Monorail Door finds its applications in a wide range of industries and settings. It is particularly well-suited for large-scale cold storage warehouses where efficient and frequent access is essential.Industries such as food and beverage, pharmaceuticals, logistics, and distribution rely on these doors to maintain the integrity of their products. The monorail system enables easy operation even in spaces with limited clearance, making it an optimal solution for areas where swing doors might be impractical.

Technical Excellence: The Cold Room Monorail Door is crafted with meticulous attention to detail. Its cutting-edge design incorporates high-quality insulation materials, such as Polyurethane (PU) or Polyisocyanurate (PIR), to create an airtight barrier against temperature fluctuations. The monorail system ensures smooth and reliable sliding motion, minimizing energy loss during opening and closing. Reinforced hinges and precision sealing mechanisms enhance its thermal performance, making it an ideal choice for cold storage facilities that require utmost precision in temperature control.

Cold Storage Warehouses: In expansive cold storage warehouses, the Cold Room Monorail Door plays a crucial role in optimizing the storage and retrieval processes. Its seamless sliding mechanism ensures swift access to the storage area, reducing energy loss and maintaining consistent temperatures. This is particularly beneficial for preserving perishable goods and preventing temperature-sensitive items from spoilage.

Distribution Centers and Logistics: Efficient logistics operations require swift and secure access to cold storage areas. The Cold Room Monorail Door facilitates the movement of goods, ensuring that perishable products are stored and retrieved without compromising their quality. Its robust construction and insulation capabilities contribute to the overall efficiency of distribution centers.

In conclusion, the Cold Room Monorail Door is a pinnacle of technical innovation in cold storage solutions. Its advanced features and precision engineering make it an asset for various industries, including cold storage warehouses, pharmaceutical facilities, healthcare institutions, and distribution centers. With its seamless sliding motion, energy-efficient design, and reliable temperature control, the Cold Room Monorail Door stands as a testament to modern engineering’s commitment to enhancing efficiency and performance in critical environments.